Counter Pressure Bottle Filler

Kegging saves a lot of time and effort compared to bottling beer, however sometimes you need to get carbonated beer out of a keg and into a bottle. Building a counter pressure filler makes this easy. The basic principle is to fill a bottle with c02 at the same pressure as the keg, connect the bottle to the beer side of the keg, gradually release the c02 to fill the bottle with beer and cap. Because the pressure in the bottle is the same as the keg there is very little foaming and minimal loss of carbonation.

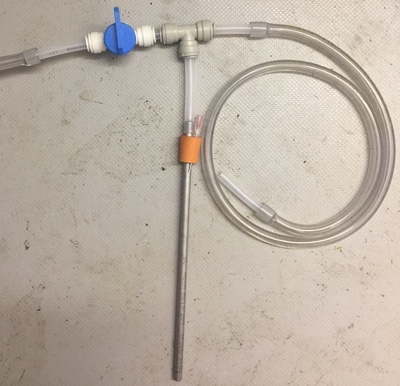

I built a filler after

looking at a few designs online. The left hand side is

connected to my regulator and the right hand side to a picnic tap attached to the keg. The spike is inserted into

the bottle, the valve opened to fill with gas with finger over the needle, valve closed, picnic tap opened and gas

gradually released to fill the bottle with beer.

I built a filler after

looking at a few designs online. The left hand side is

connected to my regulator and the right hand side to a picnic tap attached to the keg. The spike is inserted into

the bottle, the valve opened to fill with gas with finger over the needle, valve closed, picnic tap opened and gas

gradually released to fill the bottle with beer.

Parts list:

- Bevlex 200 3/16 thick walled beer line

- 3/8” outer diameter hard gas/beer line

- Shut-off valve 3/8” pushfitting

- 3/16 equal tee pushfitting

- 17mm top diameter rubber stopper

- 7mm outer diameter 25cm hollow steel tube (not sure where to get this, got some from a fellow brewer)

- Needle

Suppliers:

Suppliers:

- Keg Solutions

- Specialised Dispense Systems

- Lab/Science supply shop (stopper)

- Pharmacy (needle)

The thick walled beer line is more expensive than the thin gas/beer line but more flexible making the filler and bottle easier to handle. You could probably skip the steel tube and just use hard gas/beer line instead. It needs to get within a couple of centimeters of the bottom of the bottle. The soft beer line fits over the hard stuff if you heat it up with boiling water. Likewise the hard beer line fits over the steel tube in the same way.

I drilled the stopper using 4mm, 5mm and then 6mm wood drill bits from the small side.

The needle needs to poke through the stopper

to let gas out.

The needle needs to poke through the stopper

to let gas out.

The hard beer line fits snugly into a picnic tap.

Inspiration for this project:

And we have beer in the bottle!

And we have beer in the bottle!